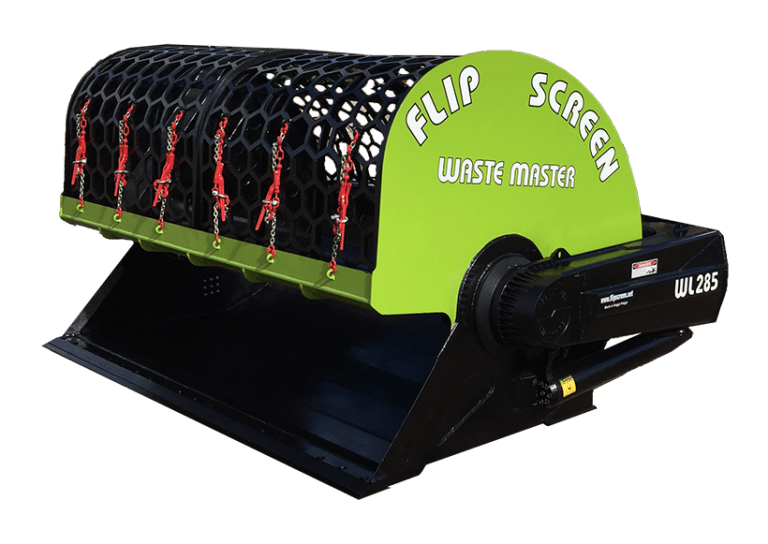

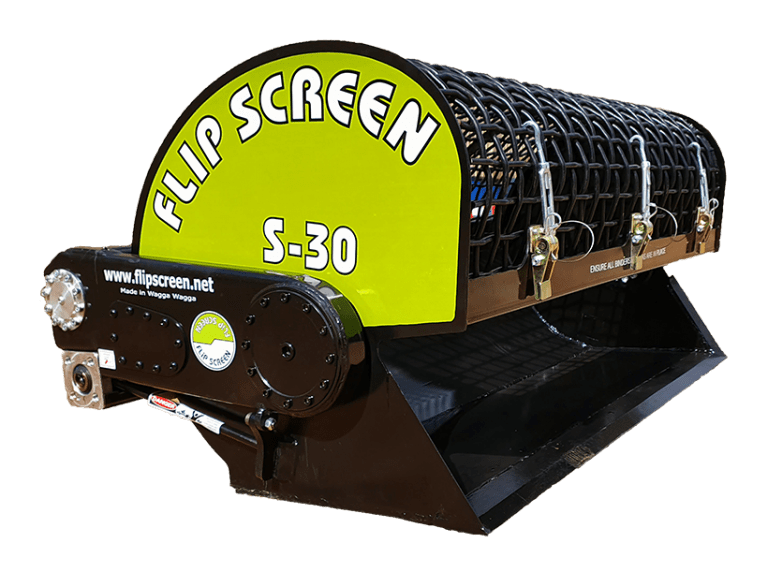

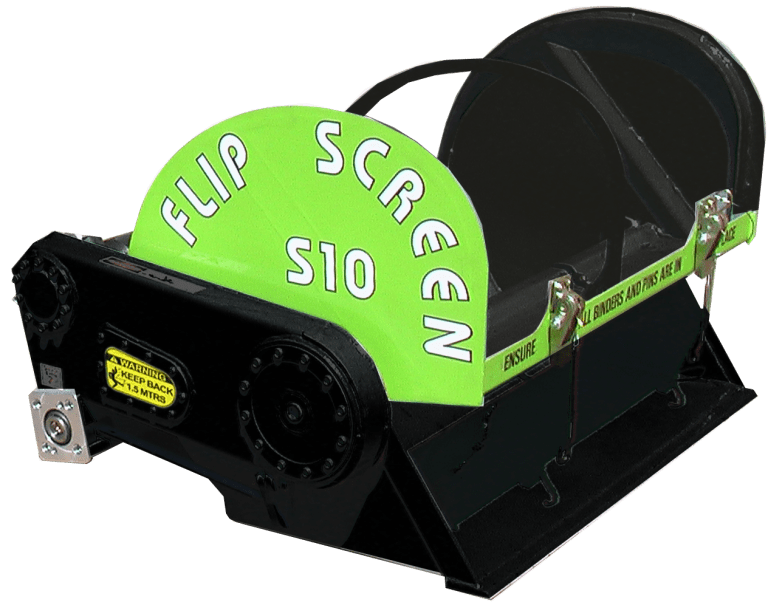

"This thing works great! The big advantage I'm seeing is you only have to handle the material one time. You can screen right where it needs to be. And they sell different size screens for it too. The brush keeps the screen clean and from clogging up, and since its not a vibratory machine, its not shaking itself apart the whole time. You can also screen directly into a truck, dirt in one and your rock into another or wherever you need it."

Andrew Camarata

CAMARATA PROPERTY MAINTENANCE - Saugerties, NY 12477